Optimization Task

In this chapter, we will learn how to define the actual optimization task for Xoptfoil2. The previous chapters should have been well understood.

Table of contents

Aerodynamic Objectives

The aerodynamic objectives of the optimization are defined with the help of so-called ‘operating points’, each of which defines a point on a polar curve of the airfoil.

For an ‘operating point’, it is then defined which property is to be changed by the optimization and how. The most common specification is: ‘Minimize drag’ at this operating point.

Depending on the degrees of freedom (number of design variables) resulting from the selected #shape function, 3 to a maximum of 15 operating points are or must be defined in order to achieve optimum results. Choosing the right operating points and defining the appropriate optimization target for this point is the key to successful airfoil optimization.

Defining an Operating Point

Two parameters are sufficient to clearly define an operating point on a polar curve:

- the Re-number

- the angle of attack ‘alpha’ or alternatively the lift coefficient cl

In most cases, better results are achieved if the operating point is defined on the basis of the lift coefficient cl. This is also the default for an operating point.

In the case of an ‘alpha’ operating point, it can happen that the optimizer wants to ‘sneak’ a low drag coefficient cd by reducing the lift. However, an ‘alpha’ operating point is needed if the objective is to optimize cl-max, i.e. cl is the value to be optimized.

To specify the Reynolds number of the operatings points, there are several convinience parameters to set default Re numbers values. The special option re_default_as_resqrtcl allows to use T2 polars as the base of optimization. In case of T2 (constant lift polar) the Re number is interpreted as Re*sqrt(cl)

&operating_conditions ! options to describe the optimization task

re_default = 400000 ! use this Reynolds number for operating points

re_default_as_resqrtcl = .false. ! interpret re number as type 2 (Re*sqrt(cl))

mach_default = 0.0 ! use this Mach number for operating points

/

Once an ‘operating point’ has been defined on a polar curve, the optimization objective for this point is now defined.

Min/Max Objectives

A typical optimization objective is to minimize or maximize an aerodynamic coefficient value of the operating point. The kind of the objective is defined by the option ‘optimzation_type’. For a min/max optimization, possible values for this option are

optimization_type | Description |

|---|---|

min-drag | Minimize drag - more correctly: minimize the drag coefficient cd |

max-glide | Maximize glide ratio ‘cl/cd’. This is equivalent to ‘min_drag’ if the operating point is defined on the basis of cl |

min-sink | Minimize the sink rate cl³/cd² |

max-lift | Maximize lift - more correctly maximize the lift coefficient cl. Only makes sense if the operating point is defined on the basis of alpha |

max-xtr | Move the laminar-turbulent transition location as far towards the trailing edge as possible. The mean value of upper and lower side is taken as the objective |

Min/max objectives should be used as sparingly as possible, as operating points usually have competing objectives and the optimization results are then no longer deterministic (see Pareto Front).

Target Objectives

Target objectives are more powerful and more versatile than min/max objectives. A target_value is specified for the operating point. If this target_value is reached during optimization, the optimizer can concentrate on the other operating points, so to speak, which leads to more reproducible results overall.

optimization_type | Description |

|---|---|

target-drag | Drag coefficient cd to be achieved for this operating point |

target-glide | Glide ratio cl/cd to be achieved for this operating point. This is equivalent to target-drag if the operating point is defined on the basis of cl. |

target-moment | Moment coefficient cm to be achieved for this operating point |

The default behaviour is that the target values may also be exceeded by an operating point (‘allow_improved_target = .true.’). In rare cases, it can be useful to reach a target value exactly and not to exceed it (‘allow_improved_target = .false’).

There is a convience option if the target_value should be based on the value of the existing seed airfoil: A negative target_value is intepreted as a factor the seeds airfoil value - e.g. target_value(i) = -1.1 lets the target value be factor 1.1 of the seed airfoil.

Reverse engineering

An interesting variant of optimization can be implemented with ‘Target Objectives’: Reverse engineering of an airfoil.

To do this, an existing polar curve, for example from a publication, is mapped with the help of 5-10 operating points and ‘target_drag’. The optimizer then generates the airfoil associated with this polar curve. If the operating points are well chosen, the result is an amazingly good reproduction of the original airfoil.

Flap Optimization

A special option is the definition of flaps. The optimization can then either be carried out with a fixed flap angle per operating point - or the flap angle becomes part of the optimization. In this case, each operating point with a flap angle to be optimized requires an additional ‘design variable’.

The definition of an optimization with flaps requires two sections:

- definition of the flap position and the hinge line

- specification per operating point, whether fixed angle or angle to be optimized

&operating_conditions ! options to describe the optimization task

use_flap = .false. ! activate flap setting or optimization

x_flap = 0.75 ! chord position of flap

y_flap = 0.0 ! vertical hinge position

y_flap_spec = 'y/c' ! ... in chord unit or 'y/t' relative to height

flap_angle_default = 0.0 ! default flap angle for all op points

! per operating point

flap_angle(1) = x ! flap angle (default: flap_angle_default)

flap_optimize(1) = .false. ! optimize this flap angle

/

Even if the flap angle is to be optimized, a reasonable starting value for the flap angle should be defined so that the initial airfoil can reach the specification value. If, for example, the glide ratio is to be optimized at c=1.6, but the initial airfoil without flaps can only reach cl=1.2, the optimization would already fail during initialization . Therefore, in this example, the flap angle should initially be set to perhaps 5 degrees.

Example

Some examples of different aerodynamic objectives of operating points

&operating_conditions ! some examples for operating points

re_default = 400000 ! Reynolds number for all operating points

use_flap = .true. ! activate flap usage

noppoint = 3 ! we define only 3 operating points

op_point(1) = 0.2 ! cl=0.2 as spec_cl is default

optimization_type(1) = 'min-drag' ! minimize cd (drag) at this point

reynolds(1) = 300000 ! individual Re number of this point

op_mode(2) = 'spec-al' ! operating point based on alpha-value

op_point(2) = 5.0 ! alpha = 5.0 degrees

optimization_type(2) = 'target-glide' ! target is glide ratio cl/cd

target_value(2) = 74.3 ! objective is a glide ratio of 74.3

op_point(3) = 1.1 ! cl = 1.1 as spec_cl is default

optimization_type(3) = 'target-drag' ! target is drag cd

target_value(3) = -1.0 ! try to preserve the value of seed airfoil

flap_angle(3) = 3.0 ! set fixed flap angle of 3.0 degrees

/

Geometric Objectives

Geometric objectives work in a very similar way to aerodynamic target objectives. They are used, for example, when the optimized airfoil should have a certain maximum thickness. Or a family of airfoils should have the same maximum camber in order to achieve a common zero lift angle.

Geometric objectives compete with aerodynamic objectives and are equally weighted in determining the objective function.

A special feature of geometric objectives is the preset_to_target option, which sets the seed airfoil to the specified target value at the start of the optimization. In many cases, this can significantly speed up the optimization - it can also be useful to ensure that the seed airfoil can reach a defined polar point at all.

Example

Some exmaples of different aerodynamic objectives of operating points

&geometry_targets ! geometry target exmaple

ngeo_targets = 2 ! no of geometry targets

target_type(1) = 'thickness' ! objective is maximum thickness

target_geo(1) = 0.09 ! target value of 9% to achieve

target_type(2) = 'thickness' ! objective is maximum thickness

target_geo(2) = 0.02 ! target value of 2% camber to achieve

weighting_geo(2) = 2.0 ! higher weighting of this target

preset_to_target(2) = .true. ! preset seed airfoil to this target

/

Objective function

At the start of an optimisation, the initial seed airfoil is evaluated at all operating points and each result is normalised to 1.0 with an individual scaling factor applied.

These individual results are then added together to form an overall result - the ‘objective function’ - which will be again normalised to 1.0. This ensures that the optimisation task begins with the value ‘1’ of the objective function for the initial seed airfoil.

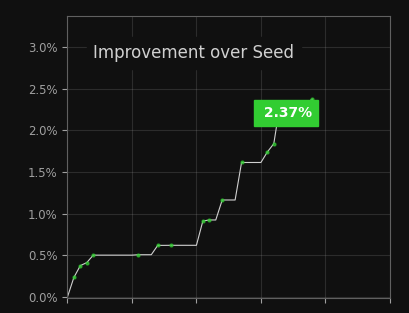

During optimization a better result will be found if the value of the objective function becomes smaller - for example, when it decreases from 1.0 to 0.92. The percentage improvement is calculated by (1.0 - 0.92) * 100 = 8%

Development of the objective function during an optimisation, shown here as “improvement”.

Multi objectives - Pareto Front

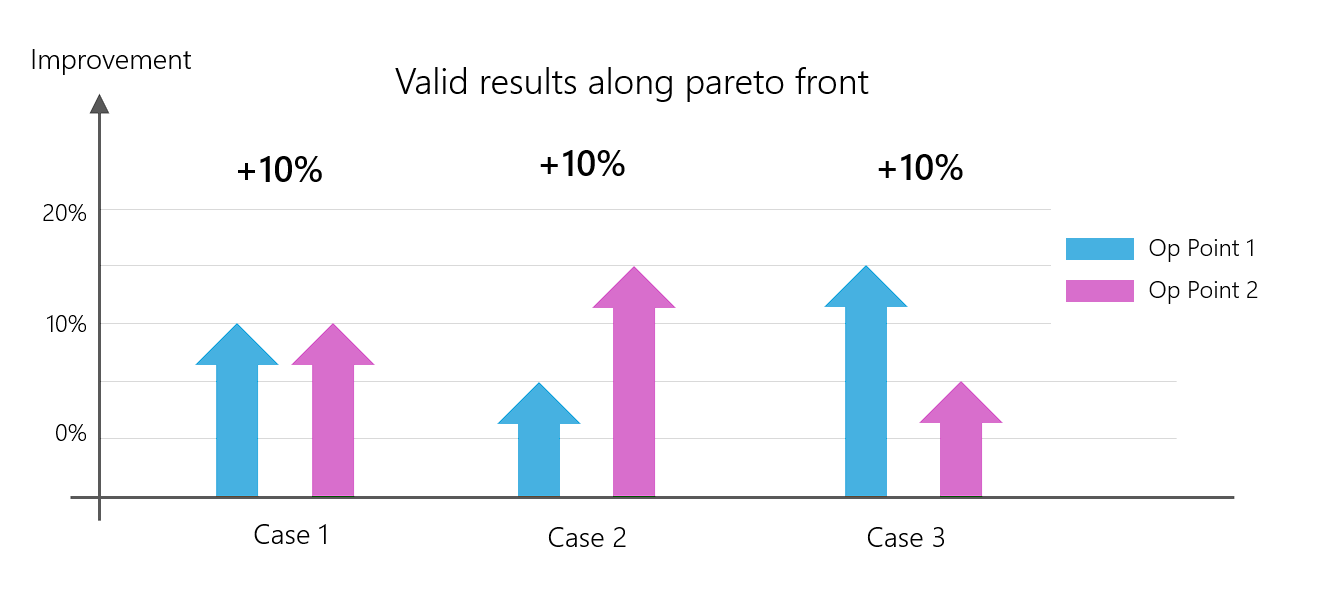

If the results of the individual operating points are combined into a single number a problem arises: the result of the optimisation is no longer clear, as different improvements at the operating points lead to the same overall result.

The (infinite) set of these individual results with the same overall result is called the ‘pareto front’.

Pareto front of an optimisation with 2 operating points. All 3 variants of an improvement at the individual operating points lead to the same overall result: +10%

Which of these 3 results is the better result? The one who defined the optimization would perhaps say “Result 2 is the best! It is particularly important for me to achieve a better improvement at operating point 2. Operating point 1 is not so important…”.

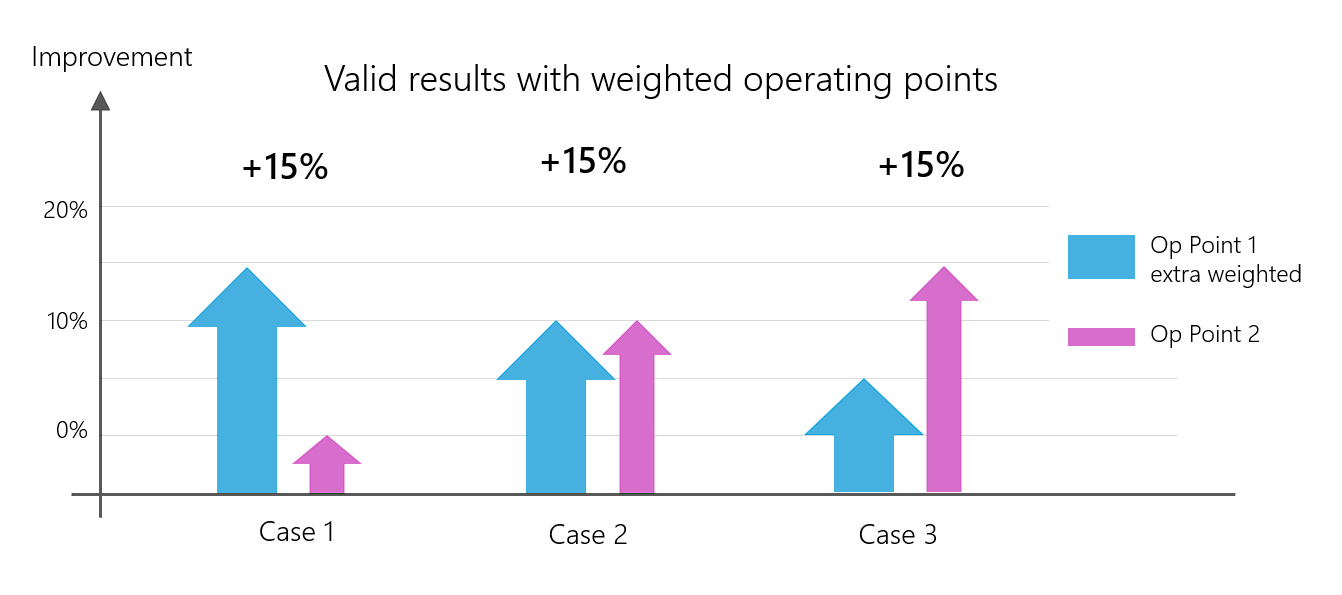

Weighting

The problem caused by the ‘pareto front’ can be mitigated by introducing a weighting per operating point. The default value for the weighting of an operating point or a geometric objective is ‘1.0’.

This weighting can be changed per operating point using the weighting() parameter.

Example:

op_mode(1) = 'spec_cl'

op_point(1) = 0.4 ! cl = 0.4

optimization_type(1) = 'min-drag' ! optimize drag

weighting(1) = 2 ! double weighting compared to default

The relationship between the results can be influenced by weighting the results of the operating points differently.

Although weighting does not improve the pareto front problem in theory, in practice it leads to clearer, more reproducible results.

Targets

A target at the operating points in the sense of “as small or as large as possible” will always lead to the effects of the pareto front.

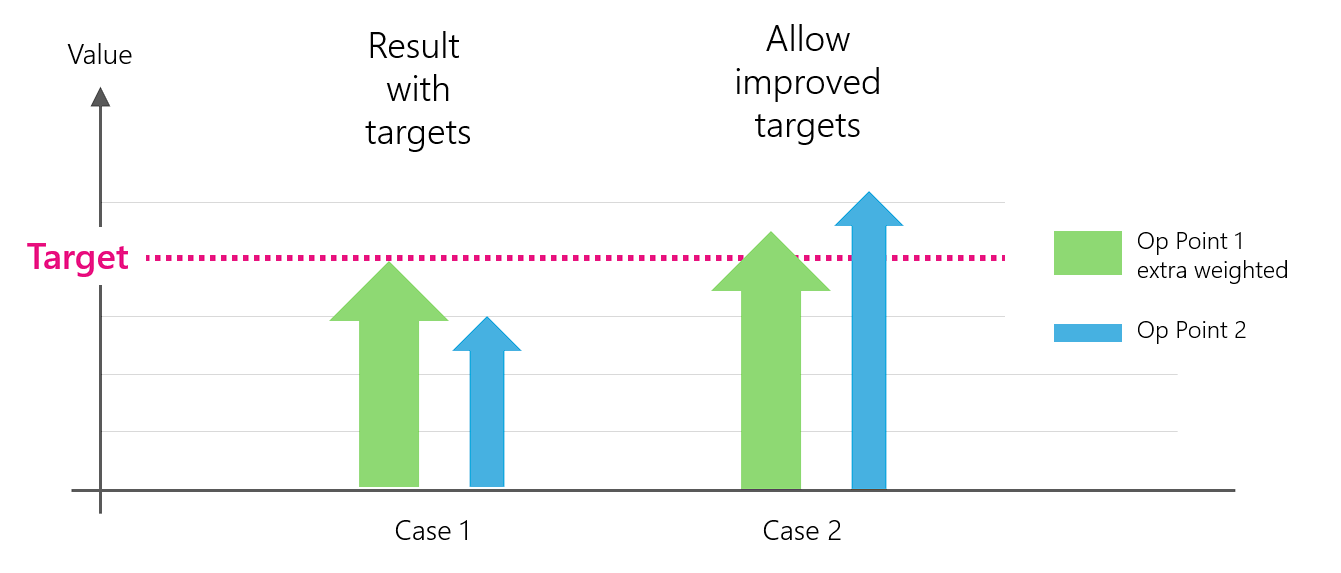

Therefore ‘targets’ have been introduced to achieve a more reproducible optimisation. They are used to define a precise target value for an operating point. Once the target value has been reached at the operating point, the optimiser can “turn to the other operating points” and try to optimise them. There are two modes for “targets”:

- the target value must be reached exactly - not larger, not smaller.

- the target value must at least be reached, but it can also “gladly” be better than the target (this is the default mode)

Example of an operating points with a target:

op_mode(1) = 'spec_cl'

op_point(1) = 0.4 ! cl = 0.4

optimization_type(1)= 'target-glide' ! glide ratio is target

target_value(1) = 74 ! try to reach at least 74

‘Targets’ allow targeted, reproducible optimisation. With ‘allow_improved_target’, a minimum value can be defined that may be exceeded.

Dynamic weighting

In order to specify a desired polar curve as precisely as possible, 8, 10 or more operating points should be specified on the polar curve on the basis of ‘targets’.

This can be time-consuming and require several attempts to balance the weighting of the individual operating points in such a way that reproducible results are achieved. Time and again, the situation can arise where the particle swarm is ‘stuck’ in a local minimum and cannot find a better solution.

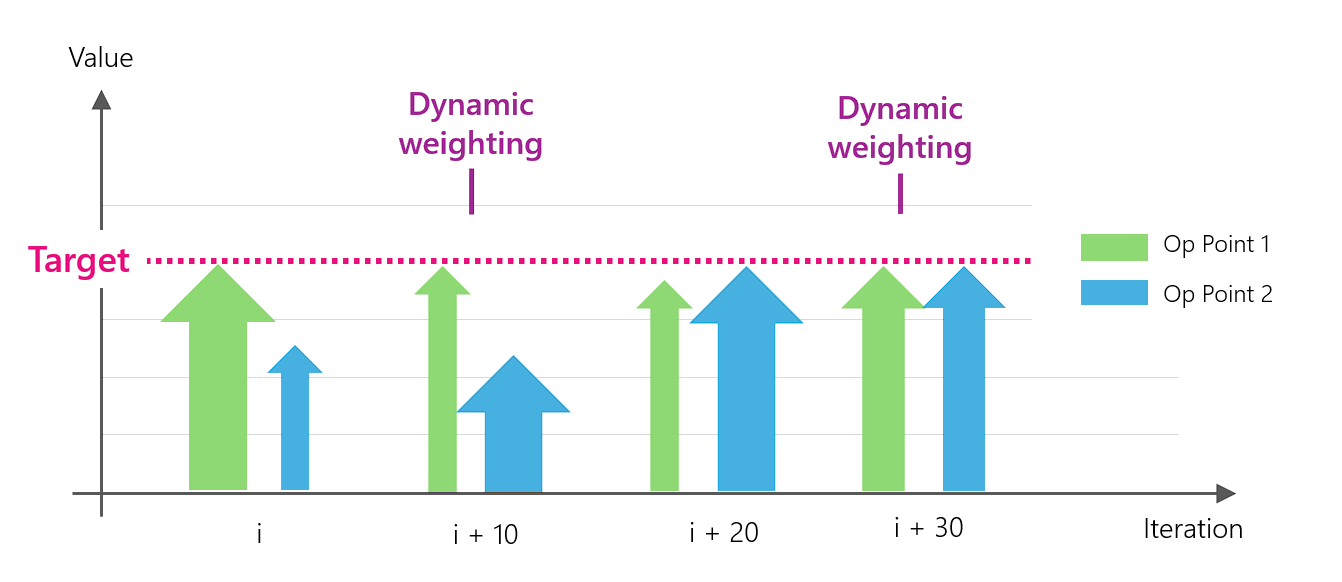

In Xoptfoil2 there is a special option for this called ‘dynamic weighting’. This involves looking at how far away the individual operating points are from their ‘targets’ for every 10 improvements achieved and carrying out a dynamic reweighting: The further away an operating point is from its target value, the higher its weighting. If all targets are designed “realistically”, this ensures that the optimisation target is achieved at all operating points.

‘Dynamic Weighting’ during an optimization run. Every 10 improvements a re-weighting of the operating points is done to ensure all operating points reach their target value.